The PBSP-74I is the latest generation in DC/AC Inverters for on-board diesel locomotive applications developed by Powerbox Australia.

This inverter has been specifically designed to power smaller driver amenity loads such as kettles, and other small AC loads found within a locomotive drivers cabin. Whilst smaller in physical dimensions and rated power output, the PBSP-74I series inverter is based on the design of the successful PBSP-74O series. The PBSP-74O series is currently used worldwide by various rail operators due to its quality, reliability and ruggedness in the harshest of environments including Australia’s Pilbara region.

Key Features

- Designed for 72Vdc Diesel Locomotive Input

- Continuous power rating of 2KW with loads of upto 2.5kw for 30 Minutes and 6kW for up to 3 seconds.

- Smaller physical footprint compared to PBSP-74O Series (4KW Variant) with package size of 445mm x 230mm x 204mm (excluding connectors, circuit breakers and circuit breaker protection brackets)

- Lighter weight construction - 18KG vs. 32KG for PBSP-740 Variant

- Wide Operating temperature: 0°C ~ +50°C (Cooling is via an internal thermostatically-controlled fan)

The PBSP-74I is a true sinewave DC/AC inverter originally designed for the retrofit of an older generation of Australian built locomotives where mounting space was a key physical constraint.

The inverter operates from a nominal 74Vdc power source and produces single phase 240Vac 50Hz sinewave power. The unit can operate loads up to 2kW continuously, loads up to 2.5kW for 30 minutes and surge loads to 6kW for up to three seconds. This high surge capability allows the inverter to operate loads with high surge currents such as motors and microwave ovens.

The PBSP-74I employs the latest low RDS(ON) power MOSFET switching technology combined with embedded microprocessor control to produce very low output distortion (less than 3%THD), at very high efficiencies (92%).

Comprehensive protection features are included. Input overvoltage and undervoltage cutouts turn the inverter off in the event the input voltage goes outside of the normal input voltage range. Firmware-controlled overpower monitoring protects the inverter against output overloads and short circuits. Automatic over temperature shutdown protects the inverter against high ambient temperatures.

The DC input power is switched and protected via a 50A 20kA miniature circuit breaker on the front of the unit. A 10A earth leakage RCBO is also connected in series with the output of the unit.

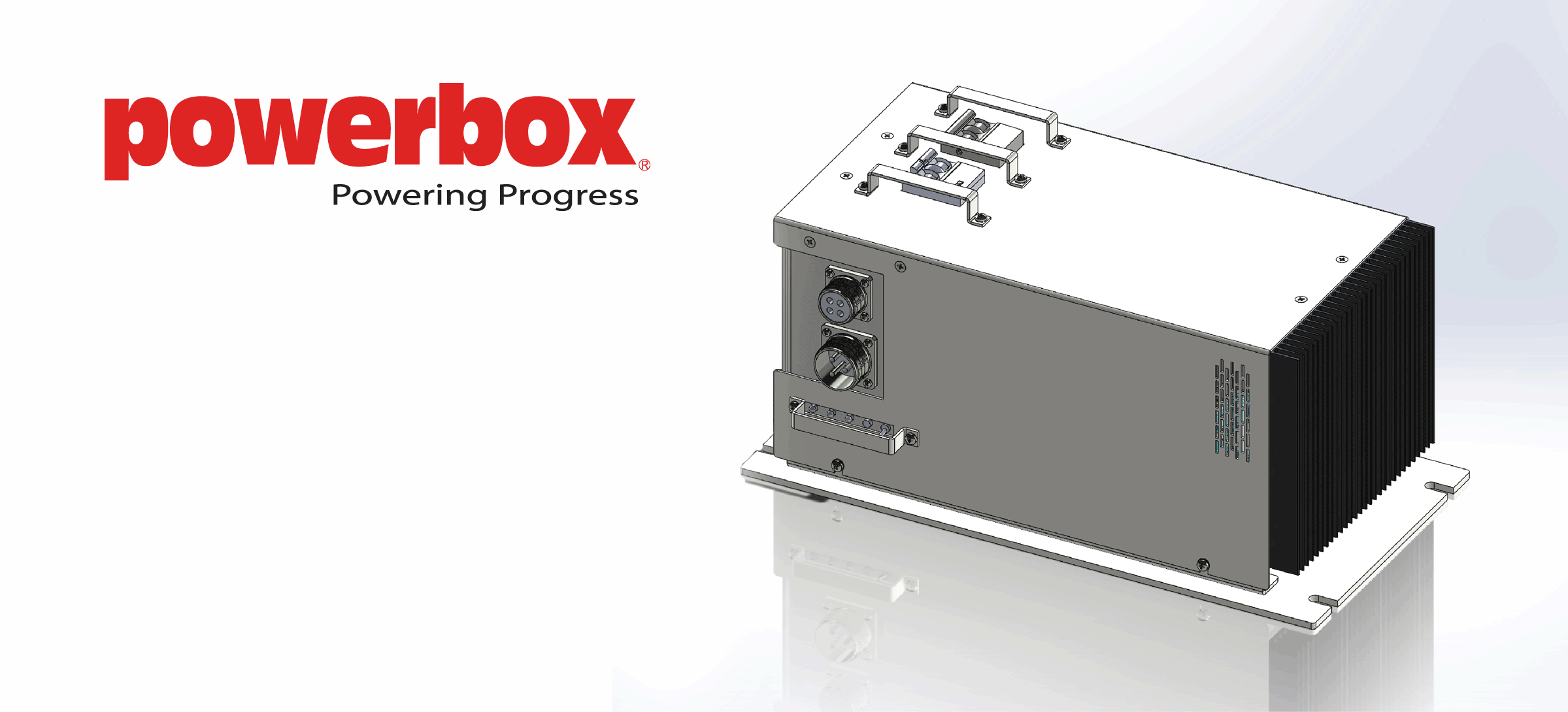

The PBSP-74I is constructed in a 445mm x 230mm x 204mm (excluding connectors, circuit breakers and circuit breaker protection brackets) powder coated aluminium enclosure suitable for vertical or horizontal mounting. It weighs approximately 18kg. The unit operates in ambient temperatures from 0°C to 50°C with relative humidity up to 95% at 40°C non-condensing. Cooling is via an internal thermostatically-controlled fan.

The PBSP-74I is designed to withstand vibration double amplitudes from 20mm at 1Hz to 0.8mm at 50Hz on all three axes and shocks of 4G longitudinally and 2G vertically and laterally.

All internal wiring is done using halogen-free low smoke RADOX125 cables.

Variant PBSP-74I-PS employs a 5mm thick aluminium mounting plate and is designed to be attached to two horizontal struts using M8 hardware via slots on the top and bottom edges of this plate. DC input and AC output connectors are mounted on the right side of the unit. The input connector is a Spacecraft SCP02YJ22-2P F80 three pin chassis receptacle or equivalent. The output connector is a Spacecraft SCP02YJ18-10S F80 four socket chassis receptacle or equivalent. Right angle mating plugs are provided with the unit: Spacecraft SCP08FJ22-2S F80 with three #8 AWG / 10mm2 pins or equivalent for the input and Spacecraft SCP08FJ18-10P F80 with four #12 AWG / 4mm2 sockets or equivalent for the output.

Alternate variants to meet individual requirements for fleet operators and maintenance providers can be developed on request.

Download